RAISE European Project, coordinated by the group of Electrical Machines and Drives – MeltingLab of University of Modena and Reggio Emilia (UniMoRe), aims at offering solutions to improve the reliability of power converters, of machines and of the entire electric drive, without damaging their performance and efficiency. Benefits and ameliorations that are likely to exert positive repercussions in both the short and the long term, besides being exploited by manufacturers to face the competitive Asian market.

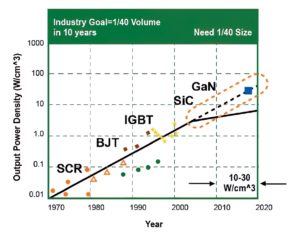

In recent years, the need of implementing increasingly powerful, light and efficient electric and electronic devices has become a priority target in all industrial sectors. For this reason, the release on the market of new wide bandgap based power devices, made of silicon carbide (SiC) and gallium nitride (GaN) semiconductor materials, has aroused lively interest in scientific and industrial communities.

Automotive and aerospace industries rank among those that can most benefit from these devices.

In this context, according to recent development trends focused on “More Electric Vehicle” (MEV) and “More Electric Aircraft” (MEA), the replacement of hydraulic/mechanical actuators with electric drives implies a neat improvement of efficiency and power density, which means also weight reduction, minor fuel consumption and lower emissions of noise and polluting substances.

The added-value of wide bandgap based power devices

The converters based on wide bandgap power devices feature superior characteristics than conventional devices based on silicon (Si). Such devices offer faster switchovers, minor power losses and they can operate at higher voltages and temperatures than their silicon counterparts, so allowing also a further reduction of volume and weight in converters’ cooling system.

«It is then clear – explains Dr Stefano Nuzzo, member of the research team of UniMore, University of Modena and Reggio Emilia, “Electrical Converters, Machines and Drives”, together with Professor Davide Barater, Professor Giovanni Franceschini and Mr Marco Pastura – that the new devices based on SiC and GaN semiconductors materials perfectly match the above-mentioned targets».

However, the electric stress combined with the high voltage gradients they can reach, in addition to the combined action of other environmental stresses (like temperature, pressure and humidity) can shorten the life time of the insulation system of electric motors powered by converters that use SiC and GaN semiconductors.

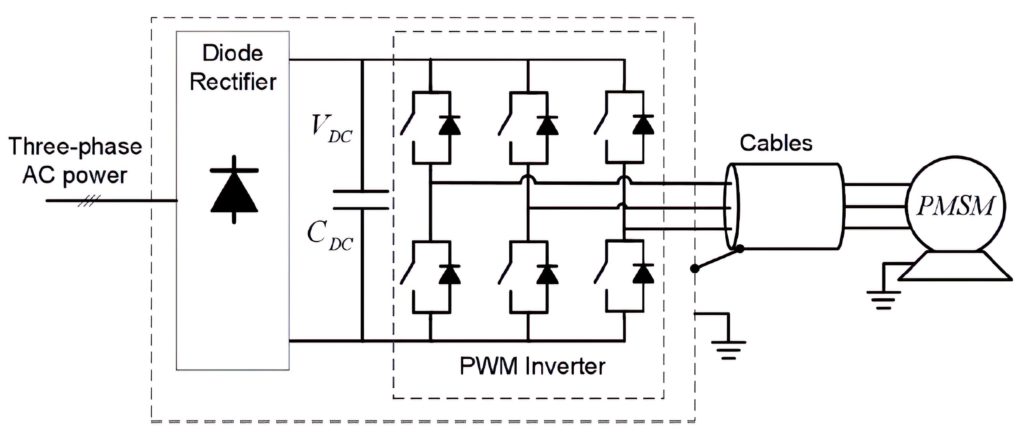

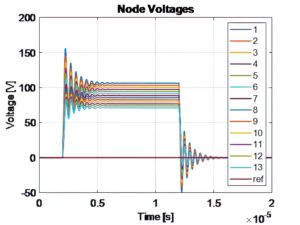

Therefore, reliability problems can emerge in this type of electric drives. Moreover, the physical length of the power supply cables that connect the power converter to the motor can be comparable, or even exceed, the so-called “critical length”. «In this case – Dr Nuzzo underlines– the high rising and falling voltage pulses make cables behave like transmission lines, with waves that travel forward and backward along cables themselves due to the reflection phenomenon. These high-frequency phenomena can cause dangerous overvoltages at motor terminals, up to twice the direct-current bus voltage, the worst case, which can seriously damage the electric insulation of motor windings».

In particular, if the values of the dielectric rigidity of insulations are exceeded because of voltage levels at electric motor terminals, conductive phenomena through a portion of the insulation material occur, leading to the so-called partial discharge phenomenon. Partial discharges occur on the surface of the electric insulation, causing a progressive erosion up to the complete breakdown. The critical length is proportional to the switchover time, therefore the very short switching times of SiC and GaN devices have made the cable use problematic even for an extension of few metres. Besides, electric power transmission networks currently proposed for aircrafts are addressing the use of higher and higher voltage levels on bus in direct current, to minimize conduction losses.

However, the voltage rise on bus in direct current causes a further stress on the stator winding insulation, thus worsening the issues connected with the use of wide bandgap based devices.

From the state-of-the-art to the progress beyond it

The project RAISE – “Reliable Aircraft electrical Insulation sElection” is framed in this context. The project, started in March 2018, is funded by Clean Sky consortium, the primary research programme on European scale, included in Horizon 2020 funding system, which aims at the development of innovative solutions for the reduction of CO2, of greenhouse gases and of the acoustic pollution. The group of Electrical Machines and Drives – MeltingLab of University of Modena and Reggio Emilia (UniMoRe), led by Professor Giovanni Franceschini, is coordinator of RAISE project and Professor Davide Barater is its Principal Investigator. Other two members of the MeltingLab assist their work in the project: Dr Stefano Nuzzo himself and Mr Marco Pastura. «MeltingLab – Dr Nuzzo specifies – collaborates with the main groups of the Department of Engineering “Enzo Ferrari”, of which it too is part, and cooperates with the most renowned area companies operating in the sectors of automotive, electric drives, industrial electronics and electrical machines».

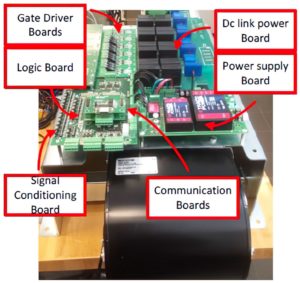

In the last years, the group’s research has focused on electric mobility, mainly working on the design of electric drives for the control of high-performance electric motors through advanced prototypes of power converters with SiC modules, and on the design of electric machines featuring high efficiency and reliability.

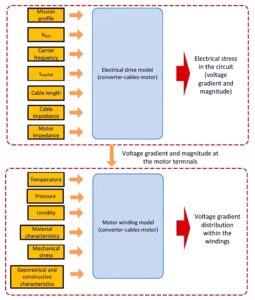

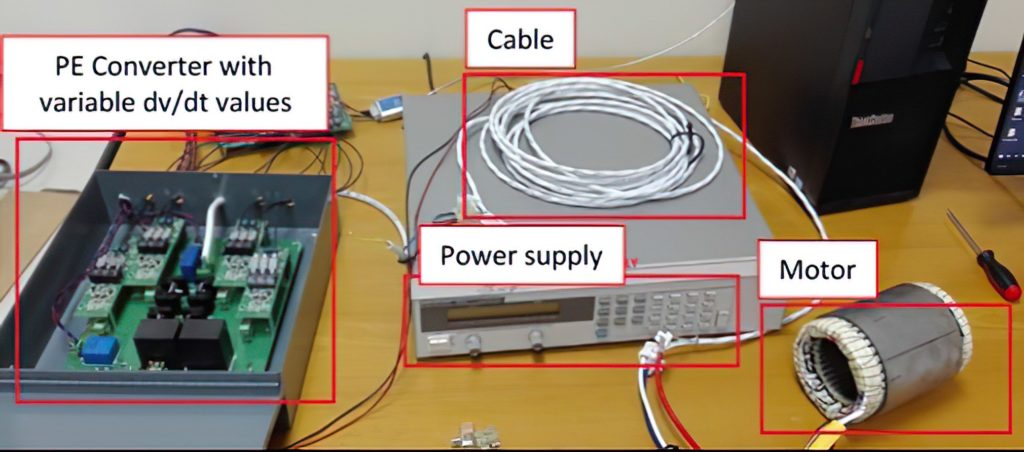

Considering all criticalities previously highlighted, it is worth first of all assessing whether the insulating materials currently in use in electrical machines and in electronic power devices are suitable for applications that exploit higher and higher power supply voltages and switching gradients, such as in the case of the wide bandgap based semiconductors previously mentioned. Therefore, the first phase of RAISE project was committed to the analysis of the state-ofthe-art and to the experimental evaluation of insulation materials and systems used in in current aerospace applications. Afterwards, to better understand the impact of high voltage gradients, they have developed some models to quantitatively assess the values observed in a typical system composed by power converter, cable and electric machine, considering the typical operating conditions of the aerospace environment and the dependence on the alternating voltage (three-phase at 115 Vrms versus 230 Vrms).

The limit for the direct-current bus voltage was fixed at 1 kV, while the maximum voltage gradient considered is 20 kV/µs. Nevertheless, for these studies, they have considered also higher voltage and gradient levels, which might be reached in the next future. «These models – Dr Nuzzo specifies– can assess also the voltage distribution inside the windings of the electric machine and its dependence on the key parameters of the machine».

(UniMoRe) and University of Bologna (UniBo). UniMore leads the consortium as project coordinator whereas the company LiebherrAerospace, multinational operating in the aerospace sector, acts as Topic Manager for the project. RAISE aims at investigating and assessing partial discharges and breakdowns of electric insulation in electrical machines’ windings driven by wide bandgap converters of silicon carbide (SiC) and gallium nitride (GaN). Goal of the project is offering solutions to improve the reliability of power converters, of machines and of the whole electric drive, without damaging performance and efficiency. Consequently, the aircraft of the future, besides being “more electric”, will be more reliable, more compact and lighter, and fuel consumptions and the environmental impact, mainly measured on CO2 emissions, will be drastically reduced. It will be possible to transfer conceptually and practically the results of the project to the automotive industry, where the same electrification trend is taking place.

Innovative methodologies to reduce high voltage gradients

The project subjected to in-depth study is also aimed at verifying when the partial discharge phenomenon on insulation systems starts. «In this second phase, – Dr Nuzzo highlights – we developed some models based on the estimation of components’ life time and we carried out some experimental tests aimed at studying the impact of the voltage variation speed on partial discharges.

The investigation was executed considering also the variations of environmental conditions in terms of temperature, humidity and pressure».

The final goal consists in making the developed models represent some guidelines for the detail design of components “free” from partial discharges, through the estimation of the service life of insulation systems. The capability of designing insulation systems free from partial discharges will allow then granting the reliability of all the components of the electric system at stake and consequently of the entire aircraft.

(by Gianandrea Mazzola)